Photobioreactor

Objectives

On Earth, the production of oxygen from carbon dioxide is ensured by photosynthesis (e.g. microalgae, higher plants), which potentially produces edible biomass (e.g. vegetables, fruits). Within MELiSSA Loop, this function is performed by the photosynthetic compartments, with a clear intensification with the Photobioreactor (i.e. 4a).

Spirulina platensis (Arthrospira platensis) have been chosen for their light energy conversion efficiency, its high pH environment that reduces contamination, and their high nutritional value. This “simple microorganisms” is as well genetically robust and able to adapt to a wide range of culture conditions, including space radiations.

Challenges and approach of the research

Investigations on Arthrospira sp. growth demonstrated its metabolic regulations are mainly by light energy availability. Consequently, its growth is limited by light energy flux inside the reactor.

Many achievements have been obtained and lead to the positive results of 80 liters of microalgae to supply one person oxygen needs. All these achievements lead to real breakthrough innovations, such as the use of optic fibers or thin-plate technology for optimizing photobioreactor volumetric productivity.

Flight experiments

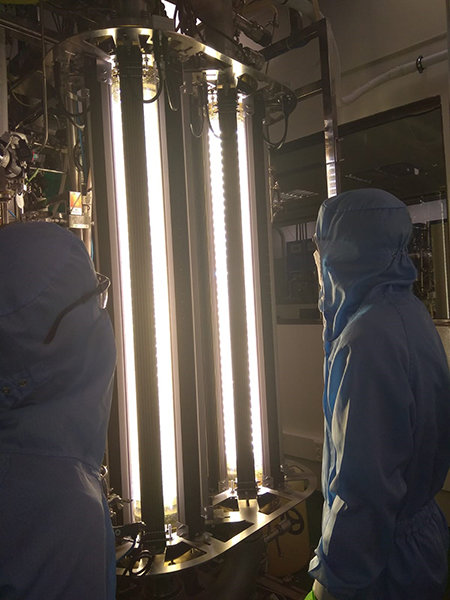

Enabling the oxygen production and a food complement during spaceflight, means the technology function appropriately in the space environment. Therefore, a representative version of the process, called ARTEMISS, was installed onboard the International Space Station for few weeks.

This experiment provided results, about the growth of the cyanobacteria Arthrospira sp. and associated oxygen production.

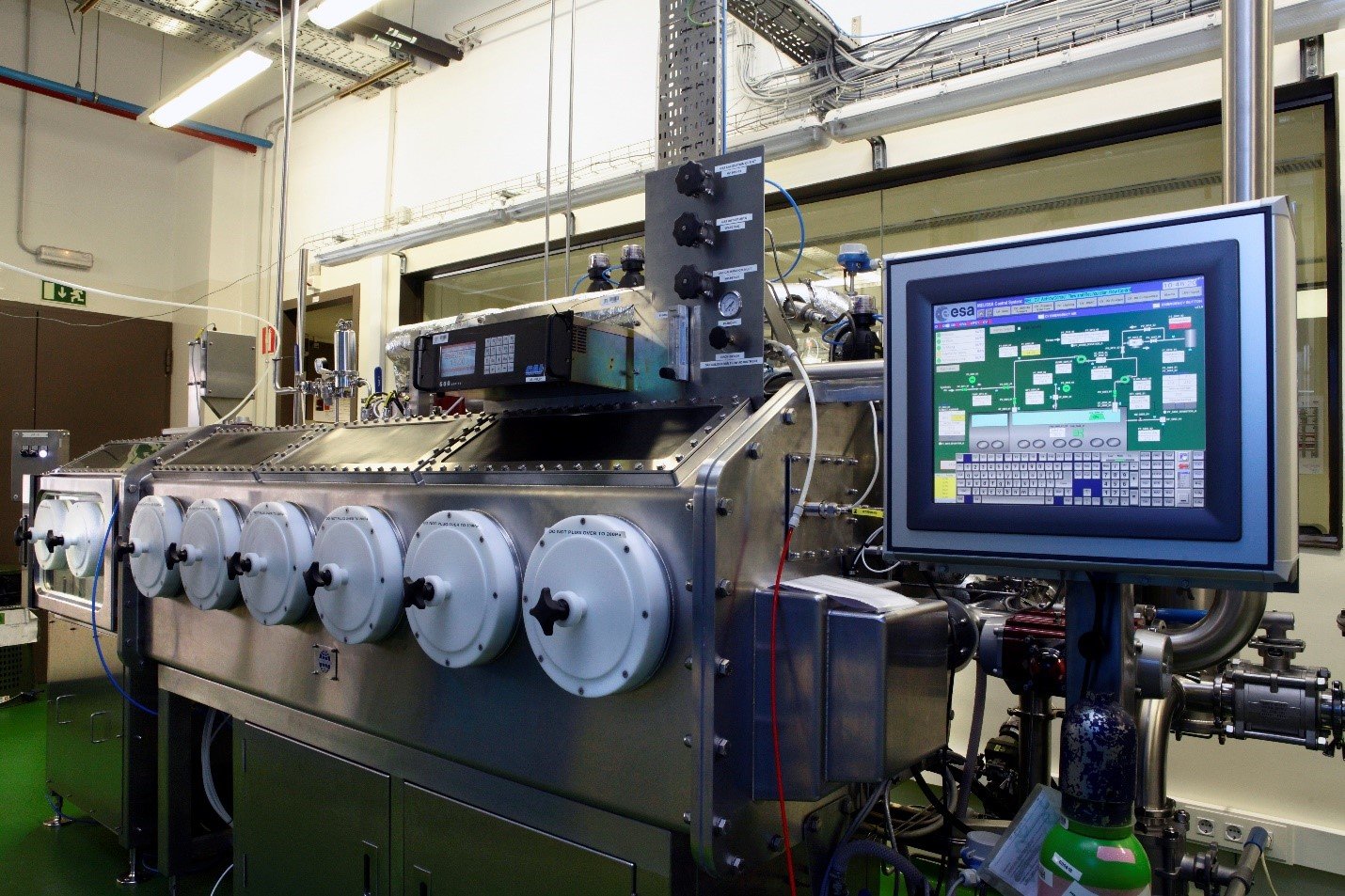

Ground Demonstration Activity

The long-term demonstration of the high robustness photobioreactor led to manufacture a 80L pilot reactor at MELiSSA Pilot Plant. Its oxygen and biomass production are completely controlled.

This system has been operated, with the objective to supply oxygen and remove carbon dioxide for our "Crew compartment". This long-term demonstration was performed without any gas buffer.

Terrestrial applications

Algosolis

Starting from the MELiSSA results, the GEPEA Laboratory (Joint Research Unit of the University of Nantes, CNRS, Oniris, EMN) has developed the AlgoSolis R&D Facilty.

AlgoSolis provides scientific and technological environment for developing optimized strains, processes and methods for the industrial applications requesting mass-scale production of microalgae.

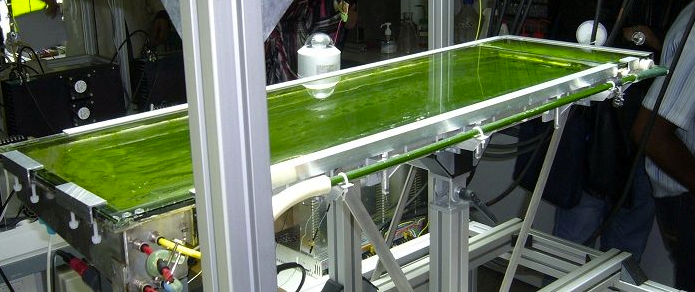

XTU biofacade

The XTU Architects firm and its partners from the SymBIO2 consortium have made a goal to develop highly innovative technologies in order to capture the significant potential of microalgae and achieve sustainable cities.

The intensified MELiSSA technologies, particularly the planar thin photobioreactors, are perfectly adapted to be a highly productive «curtain wall photobioreactor», thereby forming the actual building facade.

These photobioreactors maximise the use of solar flux for both microalgae cultures and temperature regulation, reduce water consumption for algae culture by nearly 90% compared to classic open-pond cultures, and have a volumetric productivity 30 times higher than open pounds.

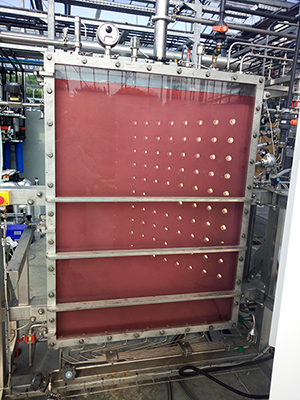

EZ Col

As part of its search for food ingredients, the MELiSSA project tested a photosynthetic bacterium. This bacterium was shown to be safe and nutritious but also, remarkably, to cut levels of LDL cholesterol – the “bad” cholesterol.

With ESA’s support, spin-off company EzCOL BV was set up by IPStar BV, MELiSSA’s technology transfer partner, to continue research and market the cholesterol-diminishing bacterium.

Congo project

INSPIRATION (INtroduction of SPIRrulina in Equatorial Africa To Improve loOcal Nutrition) project was conceived and developed.

The project is aiming to develop and support the cultivation of the cyanobacteria spirulina in African communities. The bacteria is highly nutritious and can therefore make an important contribution to the fight against chronic malnutrition, which currently affects 43% of all children under five in DR Congo.

Education and communication

Schools throughout Europe signed up for the “Food from Spirulina” biological experiment, which called upon students aged 14 to 16 to perform an experiment on cyanobacteria Arthrospira platensis, also known as Spirulina.

As part of ESA astronaut Samantha Cristoforetti’s education and outreach programm, ESA education in collaboration with ESA/MELiSSA scientists developed an experimental kit to be used in the classroom.

Food from Spirulina in-flight call with Samantha Cristoforetti on the ISS